- HOME >>

- PRODUCT >>

- BIDE Crimping Tools >>

- Pneumatic Machines >>

- View Details >>

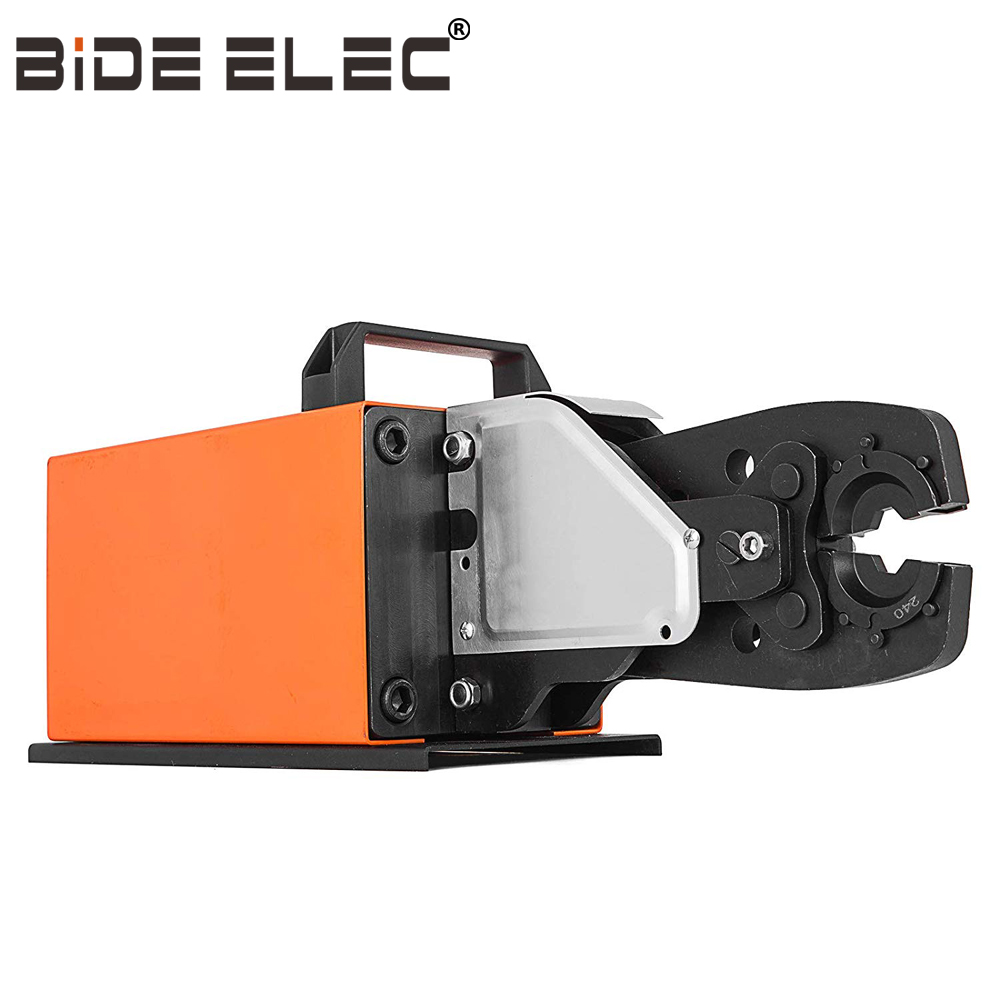

PCM-240 Pneumatic SC Copper Terminal Crimping Machine Max 240mm2

Market Price: 550

Wholesale Price:$ 510.00

- Pneumatic cold pressing terminal crimping machine, also known as pneumatic terminal crimping clamp or pneumatic terminal crimping tool, is a tool that provides power (without plug-in) by connecting the input air energy of air compressor, which solves the problems of manual crimping tools such as tedious, laborious and low efficiency ;

Pneumatic terminal crimping tools are mainly used to crimp cold pressed terminals, such as insulated terminals, bare terminals, European tubular terminals, plug spring terminals, flag terminals, nipple crimping caps, etc., which have the characteristics of high crimping efficiency, labor-saving operation, safety and convenience ;

According to the different types of pressing connection, Pneumatic terminal crimping machine can be divided into special-purpose type and multi-functional type; according to the different operation modes, it can be divided into handheld type and desktop type ;

In fact, through the design of different types of crimping machine, the feasibility of different types of terminals can be greatly increased ;

Red copper terminal pneumatic crimping machine PCM-240 is specially used for crimping SC red copper bare terminals, and the crimping range is 6-240mm2. After scientific and reasonable design, different sizes of crimping can be realized by changing the die, which greatly increases its practicability ;

Pressing shape of the pneumatic terminal machine PCM-240 is hexagonal or point type (customized), which has the advantages of high efficiency, good pressing effect, simple and labor-saving operation compared with the traditional hydraulic pliers and manual pliers ;

PCM-240 pneumatic terminal crimping machine is made of plastic sprayed iron, with its own fixed mounting base, which can be fixed on the desktop for terminal crimping, which improves the safety, and is widely used in large wire harness processing, complete set of power distribution cabinet processing, etc. ;

Pneumatic crimper PCM-240 has its own four pairs of molds, which are suitable for the copper terminal within 240mm2. The machine has stable and reliable quality, excellent crimping effect and high cost performance, and has been supported and recognized by customers at home and abroad;

Terminal Crimping Machine has been widely used in the field of wire crimping ;

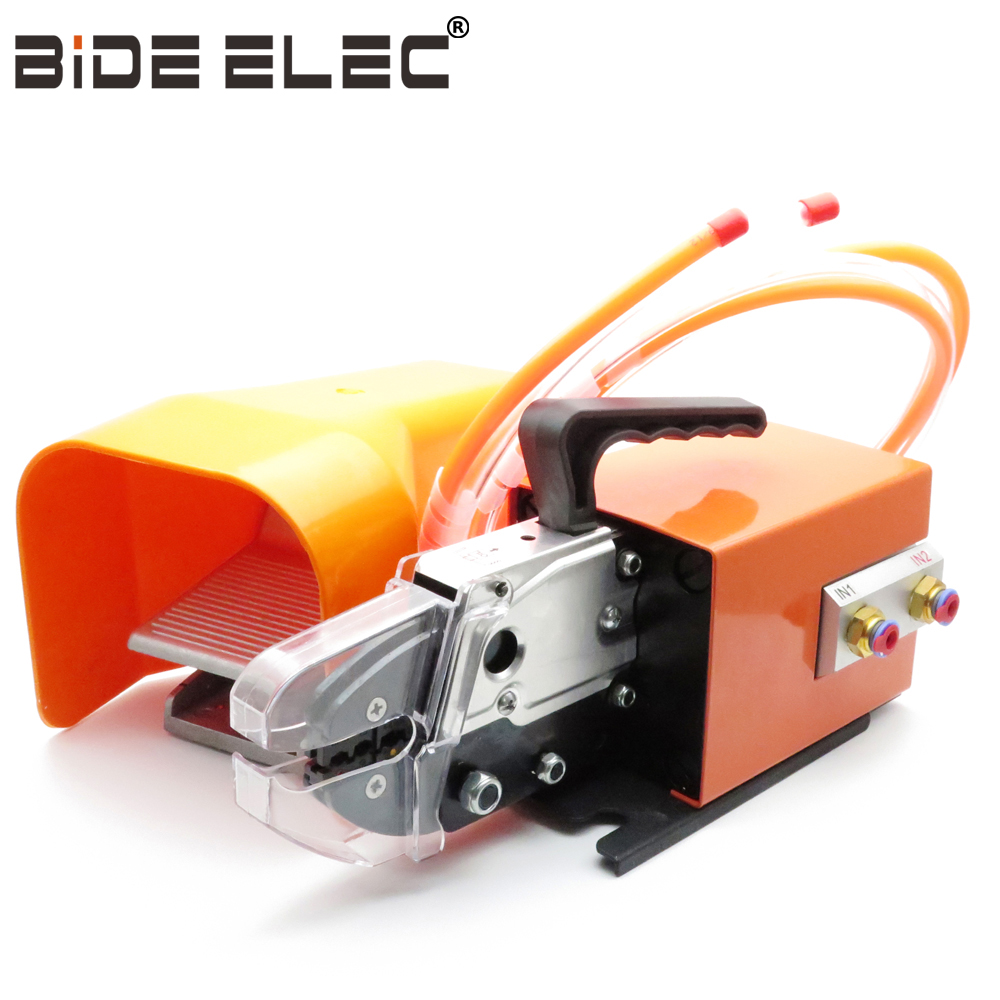

The applicable air pressure range of PCM-240 is 0.7-0.8 MPA, and the capacity of air compressor is above 35L. If the value is too small, it will affect the pressing force and crimping effect ;

Product description

Name: pneumatic wire press for copper terminals <

Applicable objects: SC terminal and copper terminal

Crimping range: 6-240mm2 < br / >

Pressure: 3T

Product size: 510 x 190 x 225 mm

Package size: & nbsp; 580 x 300 x 290 mm

Function: used for crimping large SC terminals and red copper terminals

Accessories: foot valve * 1, air pipes * 2, jaw configuration (6, 16, 25, 35, 50, 70, 95, 120, 150, 185, 240mm2)

Product characteristics

Driven by double acting standard cylinder, it has high efficiency and high quality in pressing force and pressing speed

It overcomes the shortcomings of manual or hydraulic laborious, greatly reduces the labor intensity of workers, and improves the work efficiency

It is suitable for crimping of large, medium and small terminals, and can realize confining pressure (hexagon) or point pressure

Instructions for use

Connect the tool to the air compressor, put the terminal of the wire into the pressing interface of the corresponding mold, step on the foot to complete the crimping, and then release the foot to take out the terminal

Common problems of pneumatic crimping machine

1. The air pressure does not meet the standard. If the air pressure is too high or too low, the use effect of the crimping machine will be affected, and the operation shall be carried out in strict accordance with the instructions of the corresponding tools ;

2. Shape deformation after pressing. The wire does not match the terminal, the terminal tube is empty after inserting the wire, and it is extruded or cannot be pressed after crimping , the wire is inserted into the terminal tube ;

3. The crimping efficiency is not as expected. Pneumatic crimper is a semi-automatic tool, its efficiency is affected by many convenient factors, such as crimping terminal type, terminal size, unskilled and so on ;

Publish Comments

平均

0人

-

非常好

-

很好

-

一般

-

不满意

-

很差